…We Can Help You Make It Reality!

At Sway we specialize in Product Design and Prototyping

Product Design

Do you have an idea or concept and need help formalizing it? The engineers at Sway can run with your ideas, starting from a verbal description or hand sketch to create a polished, working design. Maybe your design is further along, and you just need help to finish up. From a simple part to complex multi-part assemblies, we are a one-stop shop for product engineering.

Our skills include modelling and tolerance stacking, drawing creation, performance analysis, structural analysis, material selection, and selection of manufacturing method. We can also assist with cost analysis, quality concerns, and program management.

Prototyping

Sway is a one stop prototype shop. Analysis can get a design most of the way there, but there is no substitute for holding your part in your hands, checking for fit and verifying how well the design functions. Sway can make your parts by additive (3d printing) or traditional machining. If we don’t have the right equipment to make your parts we can help you to manage sourcing to keep your project moving forward.

Meet Us

April Tornquist

Owner

April has a BS degree in Aerospace Engineering, and has more than 20 years experience in all aspects of engineering and prototyping. She has worked with tech companies large and small, and has done freelance design and prototyping through her own company, PingOne Engineering. She is accomplished in SolidWorks, and purchased her first 3D printer more than a decade ago.

David Tornquist

Owner

Dave has a BS degree in Mechanical Engineering, and has worked in the aerospace industry for 40 years. In addition to managing programs and designing systems and products large and small, he is a certified 6-sigma blackbelt, and has developed course material and taught program management and design for six-sigma. Through his automotive hobby he has acquired machining, welding and finishing skills.

About Sway

Some years ago there was a TV commercial set in a company board room. The assembled underlings were around a long conference table, each clamoring about the importance of their function in the empire. The CEO finally quiets them. He stares at them, then proclaims “We make shirts!” Similarly, we became disillusioned with working for companies who had become so mired in processes and procedures that they had forgotten what it is that they do, or what their customers truly value. Companies that put virtually everything else ahead of true engineering and providing their customer what they need. We want to be different. But I’m getting ahead of myself.

The inception of Sway Engineering and Prototyping is really the continuation of a love story. The name Sway comes from a song of the same name as performed by Rosemary Clooney which we chose as our wedding song. April and I danced the Tango to “Sway” at our wedding in September of 2019…yeah, I know, a couple of engineers dancing a Tango? Wow! Many kudos to our dance instructor, John!

This is a many-faceted romance, and one of the things we had in common was a dream of owning our own engineering company. That we might act on that dream and form a company where WE are the bosses, where we could work together to make other people’s dreams come true…was one that we could not put down, so here we are.

The confidence that we could do this grew out of mutual respect for our complimentary engineering talents. The Yin and Yang of engineering, so to speak. April has done freelance engineering work for many years, and has experience running a business. I have a broad base of engineering experience, having been a chief engineer at a larger company for almost two decades. We both feel that we are doing what we were born to do, engineering being a passion that neither of us would give up for a career doing something else.

Our design studio is based in Gilbert Arizona, a suburb of Phoenix. With more than 60 years of engineering and fabrication experience, we can take your idea from concept on a napkin sketch through early production. Our goal is to assist our customers, large and small, in bringing their ideas to reality. We have observed that the American Spirit of ingenuity is alive and well! We see our job as helping you achieve that American dream.

Services Offered

From conception to production, we are here to help you get your project done.

Product Design/Engineering

We’ll bring your idea to life through our design process and make sure you are ready for production.

Conceptual Design

3D Design and Modeling in SolidWorks

Structural Analysis

Program Management

Root Cause Analysis

Design to Cost

Six Sigma Statistical Analysis

Test Documentation

Additive Manufacturing

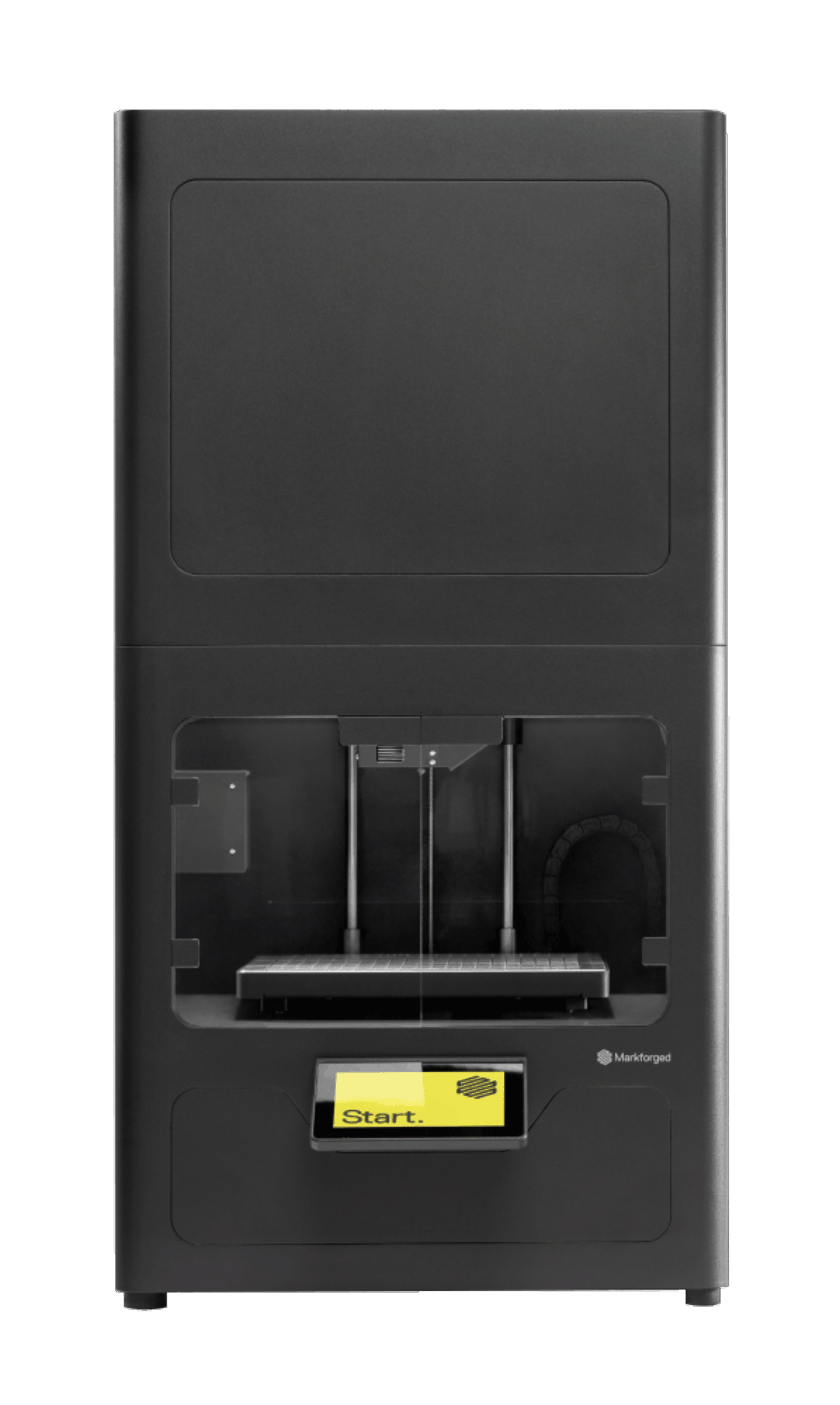

We are equiped with industrial composite and metal 3D printers by Markforged.

Composite 3D Printing

– Base Materials: Onyx, Onyx FR, Onyx ESD, Nylon White,

– Fibers: Carbon fiber, fiberglass, Kevlar®, HSHT fiberglass

Plastic 3D Printing

– Materials: Precise PLA, Smooth TPU

Metal 3D Printing

– Materials: Stainless steel (17-4), Tool steel (H13, A2, D2),

Inconel 625, Copper

3D Scanning & Inspection

We offer both 3D Scanning and inspection services utlizing the following equipment:

– Keyence VL-750 3D Scanner CMM

– Keyence XM-C1000 Handheld Probe CMM

– peel 3d (Creaform) peel 2 CAD 3D Scanner

– peel 3d (Creaform) Go!SCAN 20 3D Scanner

Prototype Fabrication, Assembly, and Testing

We are equiped with a variety of fabrication, power, and hand tools. We are your one-stop shop for engineering and prototyping.

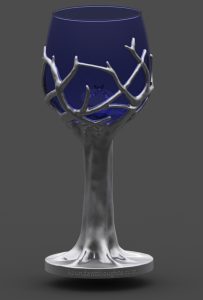

Engineering

We view Engineering not just as a science, but also as an art form, like a painting…or a dance…because generally products that perform well and look good while doing it are more successful. We call that fuctional esthetics.

- 3D model of an axe

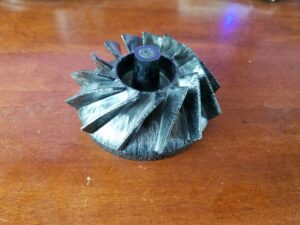

- 3D printed impeller

- April in front of a troop carrier

- The seats that April designed take a 100G shock down below 10 Gs

- Sometimes engineering really IS art!

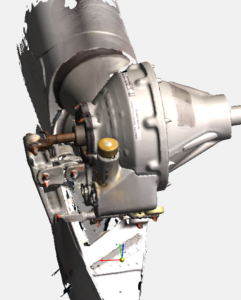

3D Scanning

Sway has the capability to scan existing parts and structures, then export the scan as an .STL file, which can then be imported into 3D CAD software like SolidWorks. Here is an example of a scan of a helicpoter tail rotor transmission using our Peel 3D Peel 2 CAD scanner! Sway can scan parts, model, and then 3D print them.

- Here is our Peel 3D scanner

- A photo of a helicopter tail rotor trasmission

- Another tail rotor transmission photo

- Here is the scanned 3D digital image

Composite 3D Printing

The X7 prints industrial-grade manufacturing jigs, jaws, tools, fixtures, and end-use parts. Designed from the ground up to survive the production floor environment and capable of printing parts stronger than machined aluminum for a fraction of the cost, the X7 delivers unparalleled surface finish, build size, and reliability. Threaded nuts can be pressed into parts during the print for embedded steel threads. Plastic threads can be printed accurately down to ¼-20 and smaller holes can be tapped.

LEARN MORE

Metal 3D Printing

The Metal X is a revolutionary 3D printer that prints metal powder bound in a plastic matrix to eliminate safety risks associated with traditional metal 3D printing methods while enabling new features like close-cell infill for reduced part weight and cost. It’s up to 10x less expensive than alternative metal additive manufacturing technologies — and up to 100x less than traditional fabrication technologies like machining or casting.

LEARN MORE

Machining

At Sway we have embraced 3D printing as a great new technology, but sometimes it isn’t the best fit for a particular project. So we can still do prototyping using traditional fabrication methods such as machining and welding. Pictured are some sample parts.

Our Portfolio

Here are highlights of some of our recent design and prototyping projects

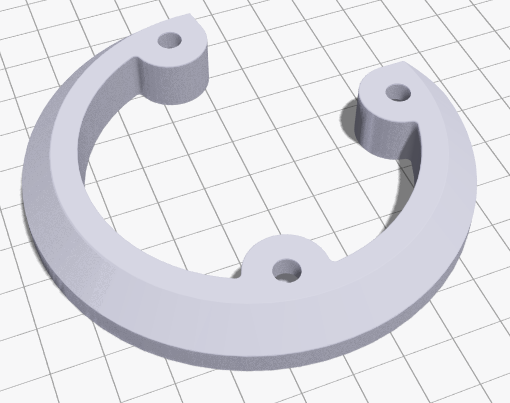

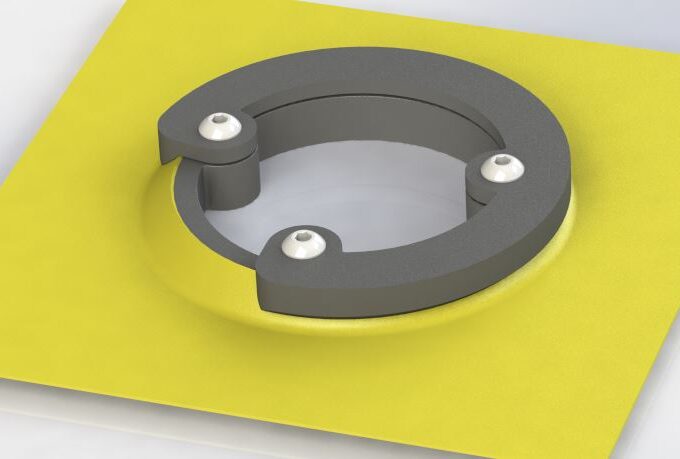

Wire Harness Pass Thru Design Project

At Sway we solve difficult design problems…like a mounting system for a wiring harness that does not create any new holes in a customer’s airframe. Here we needed to support a wiring harness where it passes through a bulkhead (in yellow). The two-piece design (in black) grips the stress relief flare at the holes in a bulkhead, and provides a place to fasten a cable clamp. This project went from rough sketch to printed parts ready for a fit check over a single weekend!

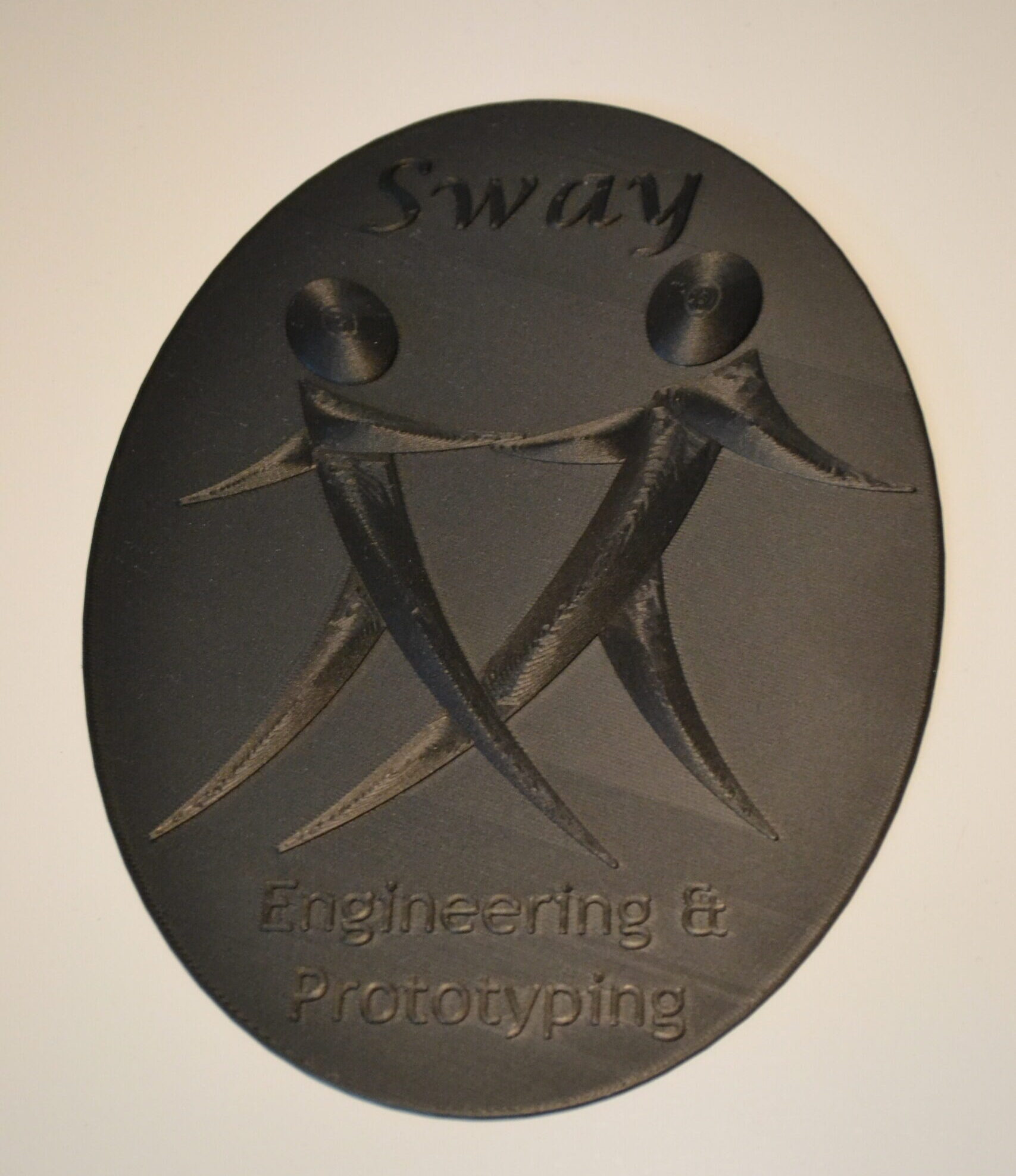

3d Print Project

Some customers have a handle on their design and just need to get their parts printed. We can do that. In this case however, the “part“ is a plaque featuring our Sway Engineering logo.

Luminescent Hat Project

Here is an example of how we can help someone realize their product idea! Scott Hundre’s project is currently featured in our “Inventor Spotlight”

Friends and Partners

MLC CAD Systems

MLC CAD Systems is one of the largest providers of CAD Training as well as resellers of CAD software and 3D printers in the US. They offer SolidWorks, Master CAM, and the line of Markforged 3D Printers.

Contact: Mandy Carlson

email:

That One Brand

That One Brand designs and markets novel consumer products like the Electro-luminescent hats featured elsewhere on this site.

Contact: Scott Hundere

email:

Clearview Design and Manufacturing

Clearview serves a similar customer base to that of SWAY, but if you need injection molding, they can help.

Contact: Thomas P Goth

email: thomasgoth@gmail.com

Inventor Spotlight

We work hard with our customers to make their dreams a reality, here’s an example:

Jason Pfaff

of

Jokawiem

Nut Butter Mixer

Learn more at No-Stir.com

See More Inventor SpotlightsOur Prayer

Yeah, we know that its unusual to bring up such things on a business web site, but we live in challenging times, where being silent to be politicaly correct is no longer the right thing to do. Our great country was founded on such notions as “In God We Trust” and “One nation under God…” We hope that you will join us:

“Lord, we thank you for your continued blessings and protection. We ask for your guidance in how we act and treat others. We ask that you guide our leaders during these trying times. We ask that you comfort those who have suffered losses. And we pray for the health and well-being of people everywhere.

We say these things in Jesus’ name,

Amen.”

Contact Us

email us:

atornquist@swayengineers.com

call us:

April Tornquist 480.600.3863

David Tornquist 480.363.5712